Applications to Monitor for Manufacturing

As a manufacturer not only do you need Business Intelligence applications to monitor your sales, purchases, stock and debtors, but you also have a production line to manage. Your manufacturing resource planning (MRP) is critical to your business and does its job in managing the processes involved in getting your product out on time according to your quality requirements.

Insights for Manufacturing

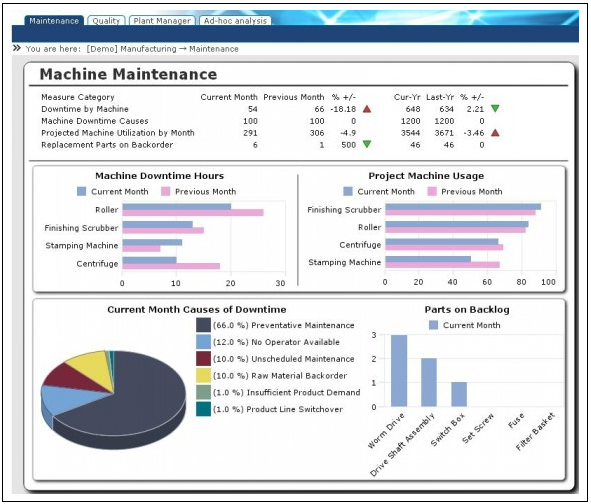

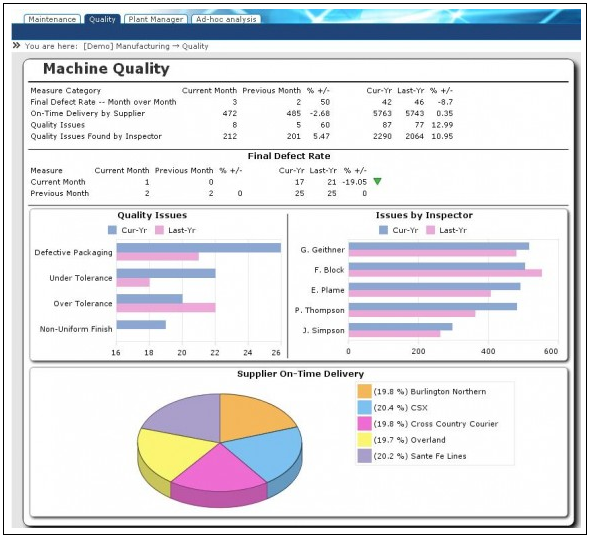

As a manufacturer you will be able to monitor and analyse information such as:

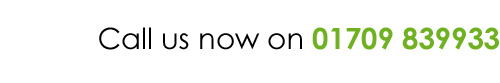

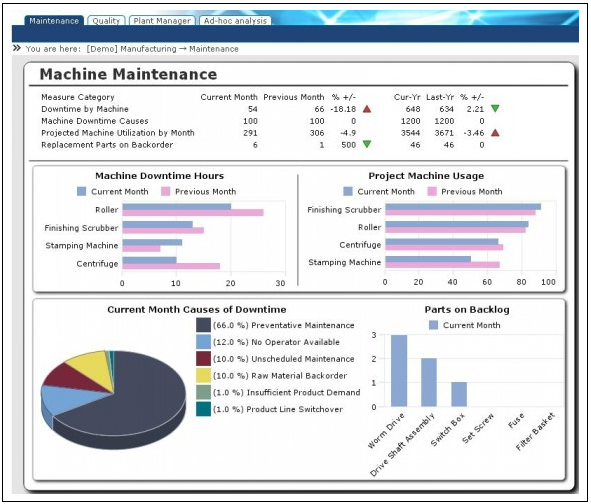

How much downtime has there been on each machine?What are the current causes of downtime and are any of them preventable?What machine parts are on back order and can I source them elsewhere?Should I be keeping more spare parts in stock?Are there more quality issues than last year and in what processes?Are some of my QA inspectors more vigilant than others?What are my defect rates?Are my suppliers delivering on time?Are my revenues meeting targets?Is my output at its full potential?Are my costs in line with budgeted costs?How many of my customer orders are delivered on time?

As well as other basics like time period comparisons of:

Yield and waste by lineCompleted units by lineUnits assembled by line/stationCompleted units by shiftSales by valueSales by volume, cases or itemsMargins by product, categoryTop productsBottom ProductsSales by categorySales by operator/FTECost per FTESales by area/salespersonStock turnsDebtor analysis and customer profilingSales vs projected sales or budget

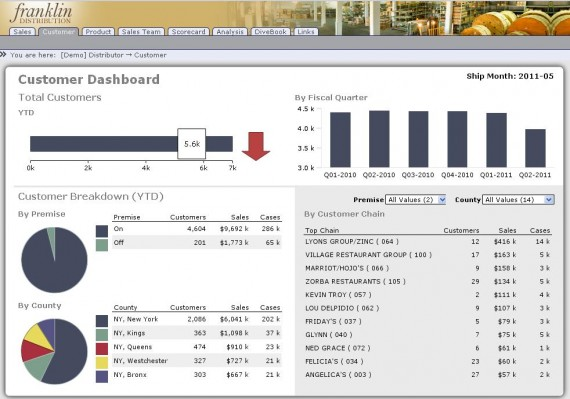

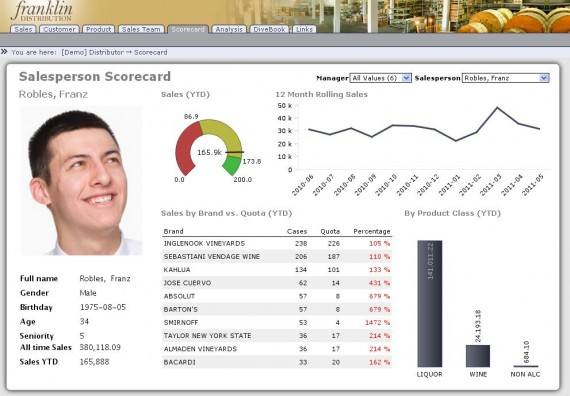

Insights for Distribution

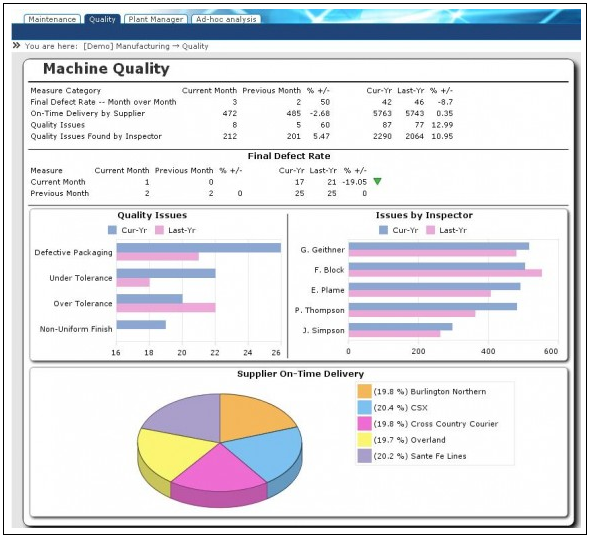

As well as the manufacturer of your product you may likely be its distributor. Diver BI will not only focus on the sales of your products but also on the cost of logistics and getting your products to your customers on time.

Analytics for Distribution

Your daily analytics will be crucial for your decisions to have a positive effect on your business. You will be able to produce data for questions such as:

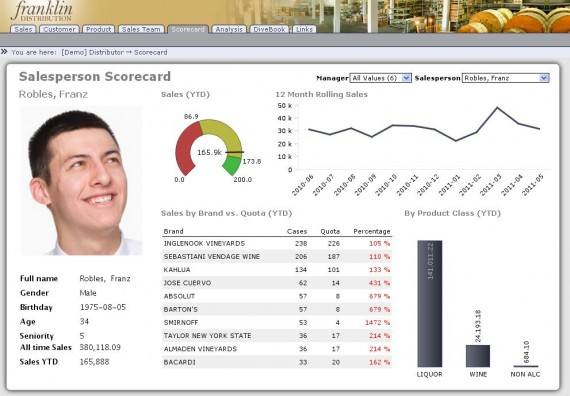

Can I compare costs per delivery, by delivery method?Are some of my delivery routes more cost effective than others?How can I combine a view of vehicle maintenance costs with staff costs from payroll to get an overall picture?How do my delivery operators compare against each other?Are there better times of day or night to drive certain routes?Can I offer better rates to customers who will order more volume, less frequently by looking at what-if scenarios?Can I reduce my carbon footprint by altering my delivery routines?Can I compare on premises sales with delivered sales and their associated real costs?What is my real margin when comparing different sale types?Are there significant differences in the performance of my sales people owing to differences in geography?

As well as other basics like trading period comparisons of:

Sales by valueSales by volume, cases or itemsMargins by product, category, department, storeTop productsBottom ProductsSales by category and departmentSales by operator/FTECost per FTESales by area/salespersonSales by supplierSales Like-for-Like across all storesSales Like-for-Like across all delivery routesSales by floor spaceStock turnsPOS movements for shelf replenishmentDebtor analysis and customer profilingHourly/daily trendsSales vs projected sales or budget